歡迎光臨,深圳市東勝達(dá)偉業(yè)科技有限公司官網(wǎng)!

時間:2022-07-20| 作者:Admin

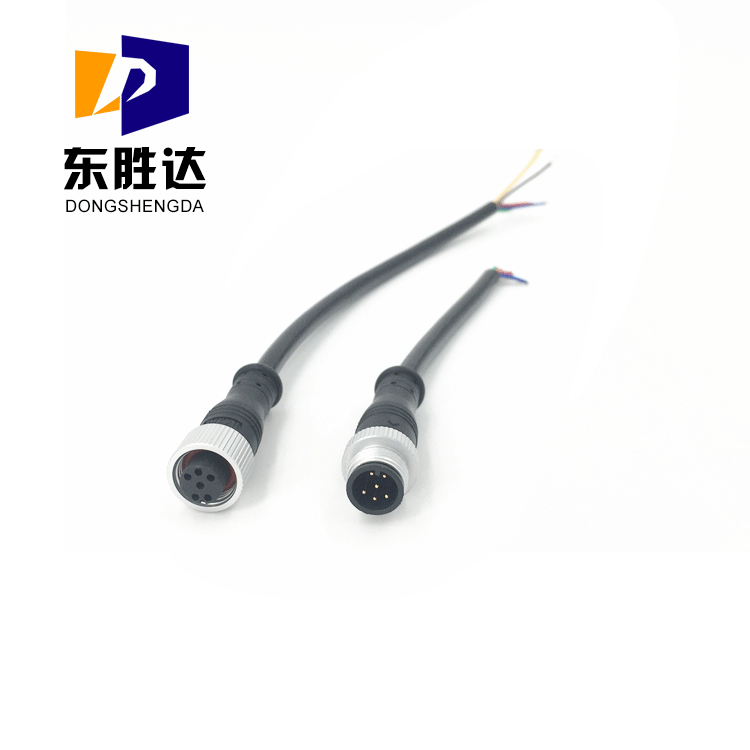

Waterproof connectorIt is a waterproof connecting component that holds a place in the connector market and is widely used in many fields, including traditional industrial production, processing and manufacturing, retail, medical services, and other fields.

Why is the performance control of waterproof connectors usually very strict? This is because in some harsh natural environments, there is a high possibility of magnetron sputtering and icing on machine equipment, so moisture resistance is a key indicator value. The application scenario of waterproof connectors themselves is usually very harsh. If the connectors cannot work properly in harsh office environments, it will not only endanger the work progress, but also continue to endanger the instruments and equipment. Stability is crucial for the connector to function properly in water.

In addition, waterproof connectors have transitioned from standard to customized products, from traditional single data signal transmission to mixed data signal transmission, and connectors are becoming increasingly modular, intelligent, and subminiature. A good connector should have excellent environmental characteristics and strong seismic resistance. With the improvement of the waterproof level of electronic equipment, it is very important to choose high-quality waterproof connectors, and the development prospects of connectors are gradually being refined and managed.

Regarding the natural environmental standards of connectors, are they subject to vibration, impact, or temperature? Fortunately, most connector manufacturers' data analysis tables will show their connector's operational capabilities under such challenges, and attention to key points will protect them from too few or too many specifications. There are also professional connectors that can be waterproof, gas resistant, and even oil resistant.

The design specifications for waterproof connectors are likely to require a necessary level of maintenance to avoid moisture, dust, and other risks. This level is generally described by an IP code, which is defined by the connector specifications and model tables. Medical and food applications are more interesting in natural environments, as are the vehicle industry, while mechanical equipment in aerospace and underwater worlds is more interesting. Combustible gases or flammable gases and liquids are likely to exist in risk areas of Level 1 and Zone 2, which is another risk that connectors must guard against.